Segmented fracturing completion process

1.Open hole completion

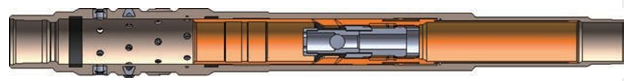

1.1Ball-drop sleeve + open hole packer stage fracturing technology

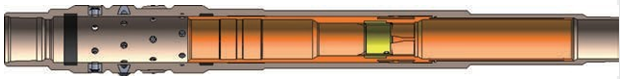

1.2 Staged fracturing technology with switchable sliding sleeveopen hole packer

Features:

-

tee has enough pressure on the performance

-

easy to drill in addition: optimization to drill in addition to the material, liable to drill in addition to the wellbore

-

special tee shape design.

-

tee large bevel design;

-

flow hole arc processing;

-

teespecial processing within the sliding sleeve

-

hardness enhancement processing

-

erosion resistance enhancement processing

-

S hole increase comprehensive treatment

2. Cementingcompletion method

2.1 CT staged fracturing technology with bottom seal

Advantages:

-

higher performance

-

higher emissions

-

more durablelonger life

-

more economic

-

apply 4-1/2 ", 5 ", 5 1/2 "casing

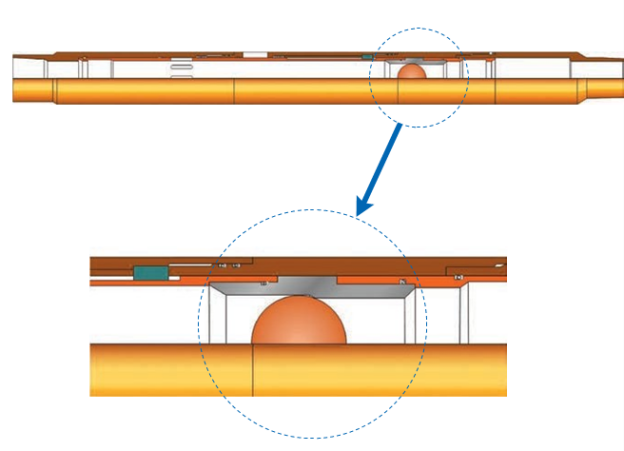

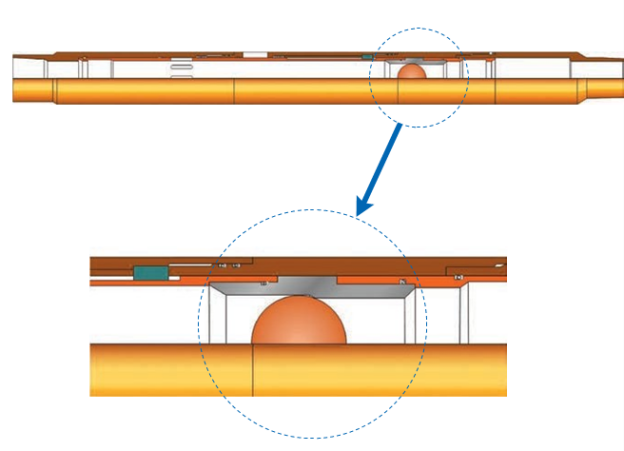

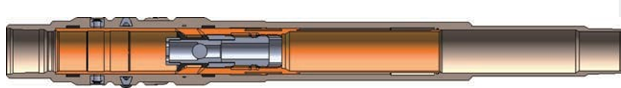

2.2 Infinitus cementing sliding sleeve fracturing technique

Advantagescharacteristics:

-

wellbore full size;

-

sliding sleeve can switch;

-

no ball seat design, do not need to drill grinding;

-

it can be used well cementing,also can be used as a conventional sliding sleeve.

2.3 Pitch cementing fracturing sleeve fracturing technique

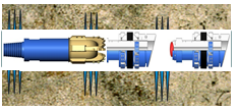

2.4 Large-diameter plug/composite plug perforating combined stage fracturing technology

2.4. 1SZ composite bridge plug system

Process characteristics:

-

using speed drillingfracturing bridge plugcable perforation coupon, casing of large hydraulic fracturing, achieve rapid multilayer fracturing

-

fixed-point selectively perforatingfracturing can be realized

-

after fracturing can quickly drill down bridge plug (about 30 minutes to drill out a)

-

material is very light, easy flowback. The fracturing scale can be large, with more than 10 layers

-

can be applied to large shale gascoal-bed methane fracturing

4.1.2 LB PnP Large diameter bridge plug system

Product features:

-

the first level according to the bottom hole pressure, temperature, can choose the double rupture disks start sliding sleeve.

-

using soluble packer was carried out on the different ball technology.

-

drift diameter design without using coiled tubing drilling bridge plug, save 30% homework time.

-

save 10% to 20% because of drillingmilling bridge plugthe cost of additional work.

-

can pumpthe deeper shaft fracturing operations, because without drilling plug.

Plug parameters:

-

provide matching different size 3.5 inches to 7 inches casing bridge plug (and can be customized according to customers requirements)

-

bridge plug standard working temperature of 175 degrees Celsius (225 degrees Celsiuscan customize according to customer demand the highest product)

-

and aiming at bottom of H2S, corrosive gasmoisture for special custom

-

maximum operating pressure 80 million mpa (can be customized according to customers requirements as much as 105 million mpa pressure product)

-

through standard ignition toolshydraulic tools for setting bridge plug

-

20 minutes he tile drill ground bridgedirectly salvage out of the well

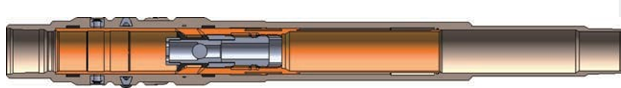

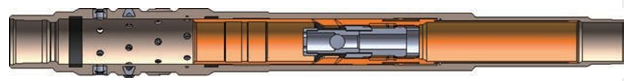

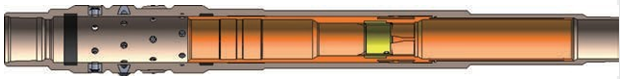

2.5 Keyway coded multi-cluster cementing sliding sleeve fracturing technology

Process principle:

-

completion: toolcasing connectionthe well at the same time, the conventional cementing;

-

fracturing: the first section of the constant pressure sliding sleeve, after fracturingsliding sleeve fracturing open the stopper is the second paragraph, fracturing the second paragraph, paragraphs shot stopper is step by step after fracturing;

-

production: pressure can be directly produced, after fracturing stopper is soluble, ball seat can drill, sliding sleeve can be selectively switch, which can realize the selective mining, looking for water plugging operation, etc

Process characteristics:

-

meet two open hole mechanism, saving the cost of completion;

-

to simplify the process pipe string structure, reduce the numberthe tool, the well completion string downeasier;

-

pressure after the stopper is soluble, do not need to drill grindingsalvage operations, wellbore full size, satisfies the requirement of subsequent construction;

-

sliding sleeve can be used to switch onoff,can realize arbitrary layer section productionlooking for water plugging operation;

-

can realize arbitrary interval perforation fracturing, reservoir reconstruction are pointed

-

within tertiary cementing sliding sleeve before size - 95 mm, the rest of the sliding sleeve - 106 - mm, after drilling in addition to the tee by special tools can open close the sliding sleeve

-

fracturing operation USES can be sol

Pour the rubber plug (soluble)the seat cover

Open frac sleeve

Dissolved rubber plug